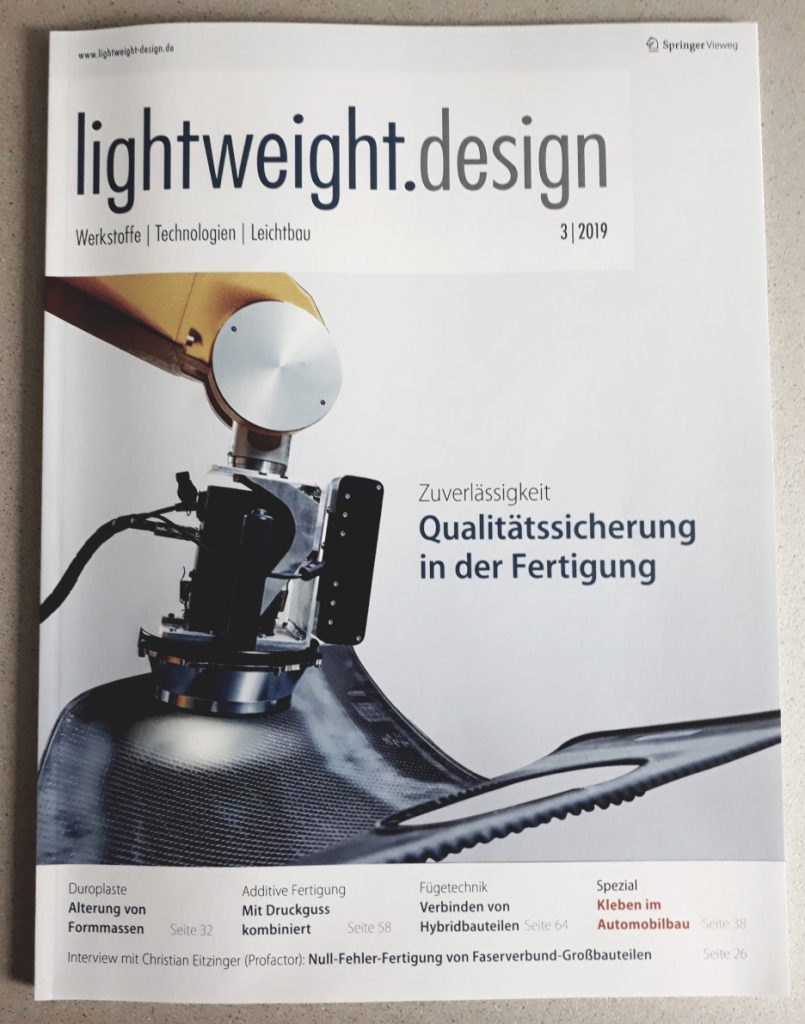

Our F-Scan is on the current cover page of the #lightweight.design magazine (springer Verlag). #FScan is a sensor technology that allows the accurate measurement of fibre angles on #composite parts. The technology can be used for different types of materials (carbon, glass) and also during different stages of the production process (raw material, pre-form, clear-coated part). Aside from measuring the orientation it allows the detection of typical defects such as inclusions or distorted fabric.

F-Scan was award with the JEC Innovation Award within the project ZAero.

The current issue of lightweight.design can be find here:

https://www.springerprofessional.de/en/lightweight-design/3404430

Zero Defect Manufaturing for industry

PROFACTOR has succesfully implemented inspection systems for metallic parts as well as composite parts in industry. Our powerful tools provide a new perspective on your production

and take you to the next level: Evolve from sorting out defective parts to avoid defects by closing the feedback loop in your production. PROFACTOR supports every step of your way, with undivided focus on your goal: Zero defects.

Folder: Zero Defect Manufacturing: Inspection systems

Folder: Zero Defect Manufacturing: Sensors with technical information

- LScan – inline control for tow-placement processes

- FScan – measurement of fibre angles on composite parts

- HScan – Inspection of drill holes in composite components

- DScan – Inspection of high-gloss surfaces