Automation in wood, metal & plastics processing with a high number of variants

When removing material manually, such as polishing, grinding or brushing, employees are often exposed to monotonous and tiring activities.

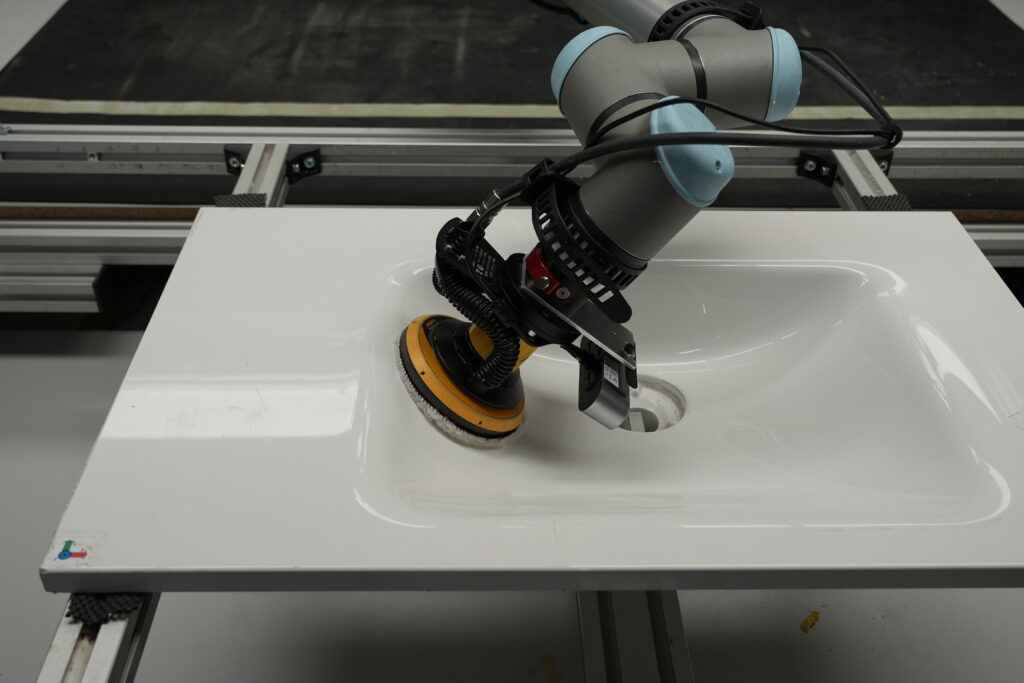

Robots can relieve employees of these tasks and, at the same time, improve quality and efficiency. One example is the spot processing of washbasins by a robot.

Processing orders can be created quickly and easily thanks to intuitive operation and 2D/3D recording of components. This is the only way to enable individual robotic processing of small quantities or even individual pieces.

The use of robot assistance systems in material removal processes can increase productivity and quality while improving workplace ergonomics at the same time.

Your Benefits

- Very short set-up times thanks to the automatic recording of the workpieces to be processed.

- Flexible and economical even with small batch sizes thanks to intuitive operation and fast order entry.

- Fast commissioning of processes thanks to the use of tried and tested hand tools. This also enables flexible switching between robotic and manual production.

- Avoidance of running costs through lower tool wear and reduced cleaning effort.

Industrial Applications

Polishing washbasins

A typical example is the polishing of washbasins. Here, a collaborative robot can carry out both general polishing tasks as well as work specifically on individual component regions (spot processing).

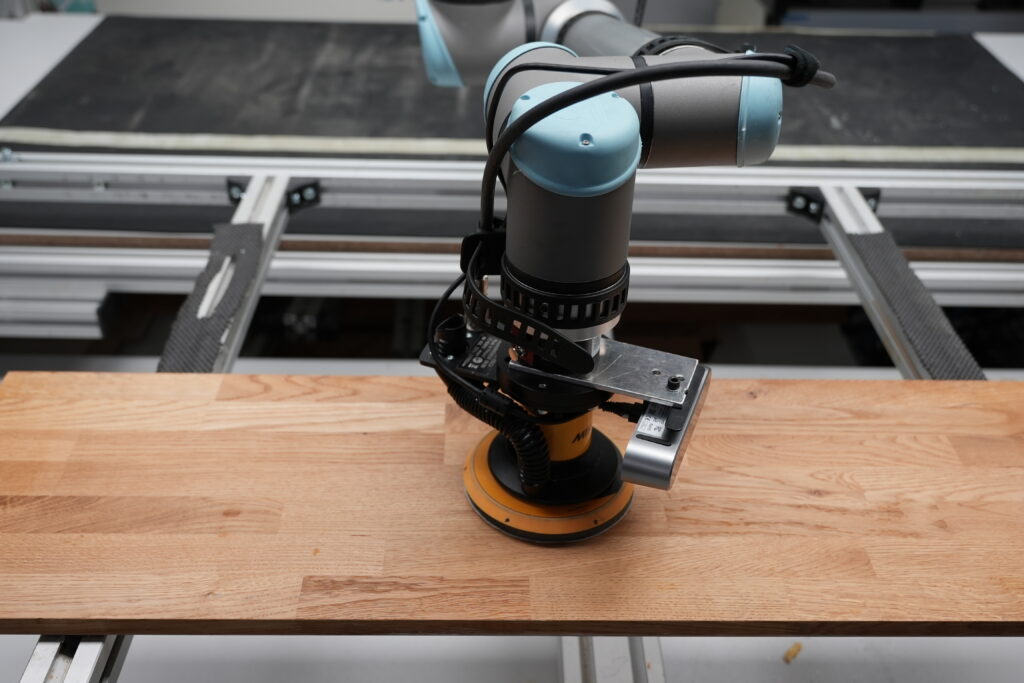

Sanding wooden panels

Other industrial applications include processes such as brushing, deburring and grinding.