DANOBAT and PROFACTOR partner up to redefine Quality Assurance for Composite Aerostructures.

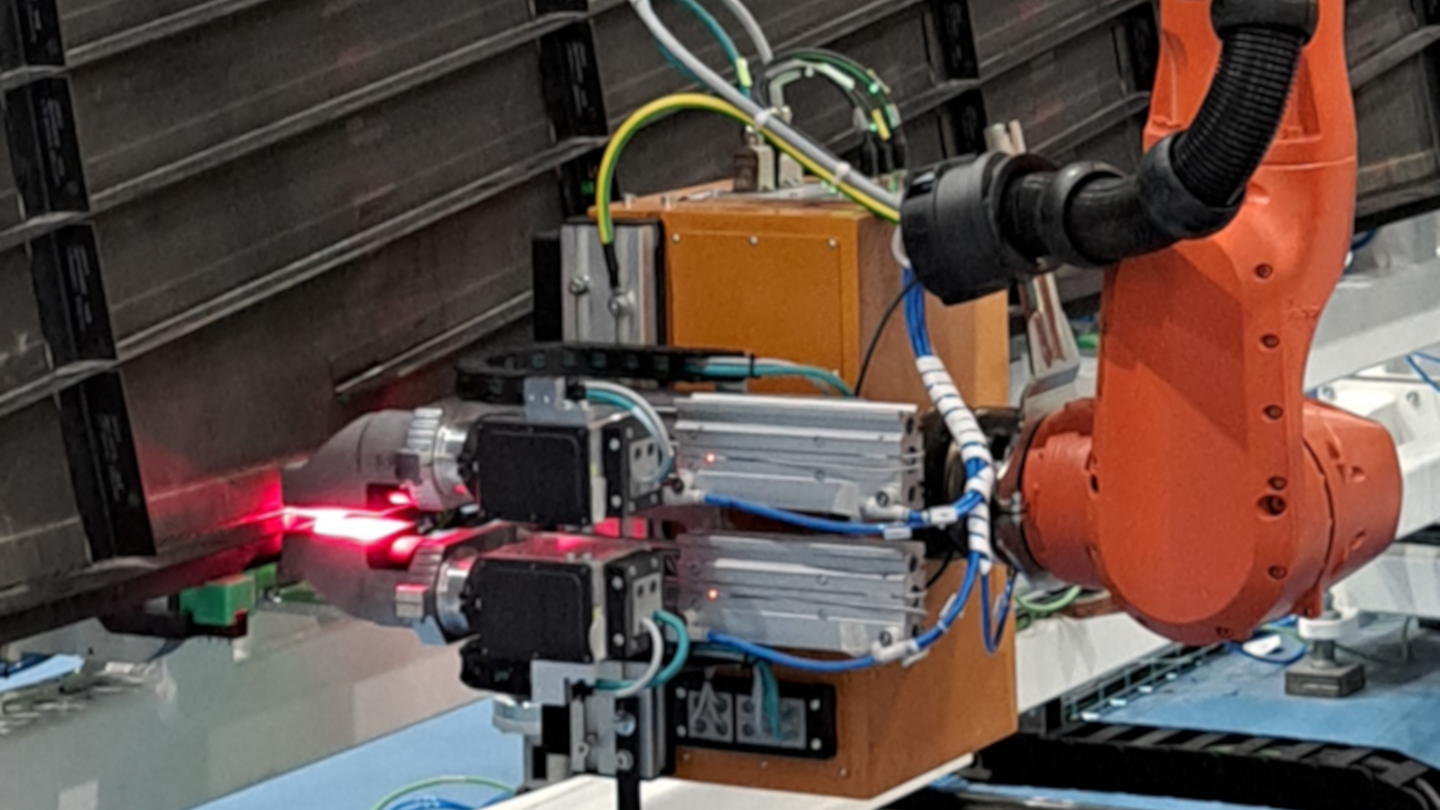

DANOBAT, a global machine tool manufacturer, and PROFACTOR GmbH, experts in composite inspection technologies, have partnered to deliver a fully automated robotic cell with innovative quality assurance processes for composite aerostructures.

As aerospace manufacturers strive for lighter, stronger, and more optimized components, the demand for efficient and reliable quality assurance continues to grow. This collaboration addresses that need in carbon composite aerostructure production by combining an automated, accurate robotic cell with advanced inspection technologies.

Specifically, PROFACTOR’s leading FScan multi-sensor inspection technology is integrated into DANOBAT’s compact robotic cells, allowing aerospace manufacturers to shift from manual visual inspections to automated, precise defect detection that meets the highest standards in record time.

This solution detects all types of defects, such as scratches, excess resin, to fiber flaking or surface pores, and also delivers high-quality documentation and actionable data for process optimization and automated rework.

Dr. Christoph Breitschopf, CEO of PROFACTOR, stated, “This partnership combines the best of both worlds – our deep expertise in inspection technologies with DANOBAT’s ability to deliver robust, integrated manufacturing solutions. Together, we’re addressing a core need in aerospace manufacturing: smarter, faster, and more reliable quality assurance.”

Xabier Alzaga, CEO of DANOBAT, added, “Our collaboration with PROFACTOR is a natural fit. By integrating their advanced inspection systems, we’re offering our customers a complete solution that not only improves production quality but also gives them a significant edge in efficiency and competitiveness.”

About DANOBAT

DANOBAT, a machine tool manufacturer, is expert in the design and development of advanced, high value-added and engineered-to-order manufacturing solutions for sectors such as aerospace, energy and automotive, among others. It is a global leader in manufacturing innovative equipment, including precision grinding machines, lathes, and robotic systems for machining.

Headquartered in the Basque Country (Spain), DANOBAT has production plants and service and sales offices all over the world, including Switzerland, Germany, the Netherlands, Italy, China, Mexico, and the United States

For more information, visit www.danobat.com

About PROFACTOR

PROFACTOR GmbH is an Austrian research and technology company specializing in industrial inspection, robotic and digital assistance systems, and additive manufacturing solutions. With decades of experience in aerospace, automotive, and production technology, PROFACTOR connects research and industry to develop customized solutions that enhance quality, efficiency, and flexibility in production processes. Their innovative approach ensures tailored solutions where standard systems fall short, speeding up advances in manufacturing and beyond.

For more information, visit www.profactor.at

Fully automated and reliable quality assurance of composite light-weight aerostructures.

PROFACTOR and DANOBAT team.