Das Projekt setzt auf den kombinierten Einsatz ausgewählter Biomaterialen und additiver Fertigungstechnik.

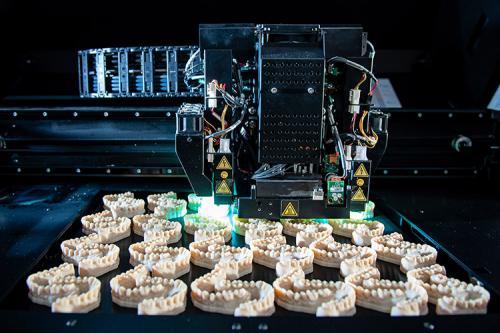

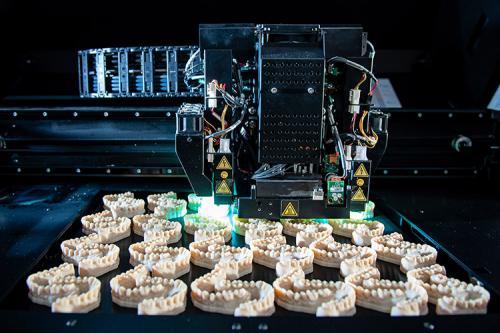

Aus Biomaterialien hergestellte Implantate, die mit modernsten Fertigungsmethoden im 3D-Druck exakt auf individuelle Bedürfnisse der Betroffenen angepasst werden: Das ist das Ziel des europäischen Forschungsprojekts INKplant, um regenerative Medizin auf ein neues Level zu heben. Das Projekt wird mit Mitteln aus dem EU-Programm Horizon 2020 gefördert und vom Produktionsforschungsinstitut Profactor in Steyr koordiniert.

Foto: Stratasys

Der Kontext

Chronische Gelenkschäden und Defekte im Mund- und Kieferbereich bedeuten für Betroffene eine stark geminderte Lebensqualität. Die dazu derzeit in der Therapie eingesetzten medizinischen Implantate stehen meist nur in Standardformen aus anorganischen, nicht resorbierbaren Materialien zur Verfügung und erfordern hochinvasive chirurgische Eingriffe und lange Rehabilitationszeiten. In einer alternden Gesellschaft führt dies auch zu stetig steigender Kostenbelastung im Gesundheitswessen.

Das Forschungsprojekt INKplant entwickelt einen radikal neuen Ansatz, der die regenerative Medizin auf ein neues, effizienteres Niveau heben soll. Durch die Verwendung von Biomaterialien und die Anwendung additiver Fertigungsmethoden wird die Herstellung individuell angepasster Implantate mit hoher Biokompatibilität ermöglicht. Ergebnisse von INKplant sollen eine leistbare personalisierte medizinische Behandlung und eine wesentliche Verbesserung der Lebensqualität der Betroffenen sein.

Das Projekt

Die zu entwickelnden Implantate sollen das biologische und mechanische Verhalten des menschlichen Hart- und Weichgewebes nachahmen. Die dafür eingesetzten Kombinationen von biokompatiblen und biologisch abbaubaren Materialien müssen in Härte, Elastizität und Porosität den Anforderungen des jeweiligen Körperteils entsprechen und dem Implantat eine stabile Verankerung und rasches Einheilen ins Gewebe erlauben. Dadurch soll die Invasivität chirurgischer Eingriffe und die Gefahr möglicher Komplikationen verringert, die Rehabilitationszeiten verkürzt und damit die Gesundheitskosten deutlich gesenkt werden.

Für die Herstellung individuell angepasster Implantate werden hochauflösende additive Fertigungstechnologien angewandt und weiterentwickelt. „Der 3D-Drucker erhält die individuellen Daten der Patient:innen aus herkömmlichen bildgebenden Diagnoseverfahren der Medizin. Mit Softwarealgorithmen wird die perfekte Geometrie und der optimale innere Aufbau des Implantats errechnet“, erklärt Projektkoordinatorin Sandra Haas. Ein wesentlicher Schritt ist die Weiterentwicklung der Biomaterialien zu Tinten für das 3D Inkjet-System, welches es dann ermöglicht, hochauflösende 3D-Strukturen zu drucken.

Neben der Entwicklung dieses Herstellungsprozesses wird im Projekt auch die Anwendung der Implantate an vier Beispielsfällen erprobt: an Defekten des Meniskus und an Knochen- oder Knorpelverletzungen im Knie, an Gaumendefekten und in der zahnmedizinischen und oralen Rehabilitation.

Das Konsortium

Profactor koordiniert das Projekt, an dem 19 Partner aus Industrie und Forschung, die aus acht Ländern kommen, zusammenarbeiten:

Die Partner:

Profactor, Österreich

Stratasys, Israel

Lithoz, Österreich

Fluidinova, Portugal

3D Matrix Europe, Frankreich

Luxinergy, Österreich

Elkem Silicones, Frankreich

Tiger Coatings, Österreich

Universidad Politecnica de Madrid, Spanien

Johannes Kepler Universität Linz, Österreich

Kepler Universitätsklinikum GmbH, Österreich

Biomed Center Innovation gGmbH, Deutschland

Ludwig Boltzmann Gesellschaft, Österreich

Medizinische Universität Wien, Österreich

Charité Universitätsmedizin Berlin, Deutschland

Transtissue Technologies GmbH, Deutschland

Biotechnology Institute, Spanien

Universitair Medisch Centrum Utrecht, Niederlande

Asociacion Espanola de Normalizacion, Spanien

Die Rolle der österreichischen Partner

Profactor: Entwicklung von Bio-Inkjet-Tinten, Druck- und Härtungsprozessen und des 5-Achs-3D-multimaterial Inkjet Druckers

Lithoz: Lithography-Based Ceramic Manufacturing Prozesse für bi-material Keramik

Luxinergy: Biologisch abbaubare Polymere für Inkjet

Tiger Coatings: Hochskalierung der Tinten, Charakterisierung und Qualitätssicherung für CE-Zertifizierung

Johannes Kepler Universität ICP: Biologisch abbaubare Polyphosphaze-Polymere für Inkjet, Charakterisierung der Biodegradierbarkeit der Tinten

Johannes Kepler Universität IPPE: Testen der biomechanischen Eigenschaften von Materialien/Designs

Kepler Universitätsklinikum: Expertise für Use Cases und in-vivo Tests

Ludwig Boltzmann Gesellschaft: Biokompatibilitätstests, in-vivo Tests

Medizinische Universität Wien: Modellierung von biomechanischen und Gewebeintegrationseigenschaften, Entwicklung von Druckdateien

Der Mehrwert eines EU-Projekts

Sandra Haas, Stellvertretende Projektkoordinatorin INKplant

Foto: Sandra Haas

„Das Besondere an einem EU Projekt ist neben der engen länderübergreifenden Kooperation auch die Involvierung eines externen Expertengremiums und der starke Fokus auf „Open Innovations“, erklärt Sandra Haas, stellvertretende Projektleiterin von INKplant.

„Das Konsortium besteht aus sehr erfahrenen Experten in sämtlichen Bereichen, von der Entwicklung über die Produktion bis zur Zertifizierung und Anwendung der neuen Implantate. Dadurch ist wertvolles Wissen im Gremium vorhanden, das dank des unglaublichen Enthusiasmus aller Partner für das Projekt und die Projektidee proaktiv ausgetauscht wird und zu neuen Erkenntnissen und Ideen führt. Die externen Experten und „Open Innovations“ Aktivitäten ermöglichen hier nochmals neue Blickwinkel auf einzelne Bereiche der Entwicklung und Lösungsansätze für neue, während der Forschungsarbeit auftretende Herausforderungen zu finden.“

DI Dr. Christian Eitzinger

DI Dr. Christian Eitzinger

Dr. Leo Schranzhofer

Dr. Leo Schranzhofer DI Dr. Michael Mühlberger

DI Dr. Michael Mühlberger On the 7th of July 2021 PROFACTOR in cooperation with GMAR invited to the TIN Tech & Trend Dialogue on Artificial Intelligence at the lake Constance in Germany. The “Lake Constance Talks” have been a great opportunity to gather policy actors, researchers & industry representatives together and to discuss hot topics of artificial intelligence in connection with automation & robotics, sustainability, energy and robotics.

On the 7th of July 2021 PROFACTOR in cooperation with GMAR invited to the TIN Tech & Trend Dialogue on Artificial Intelligence at the lake Constance in Germany. The “Lake Constance Talks” have been a great opportunity to gather policy actors, researchers & industry representatives together and to discuss hot topics of artificial intelligence in connection with automation & robotics, sustainability, energy and robotics.