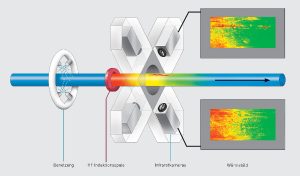

Steel-billets can be checked for cracks automatically at transportation velocities of up to 1.5m/s by inductive excitation.

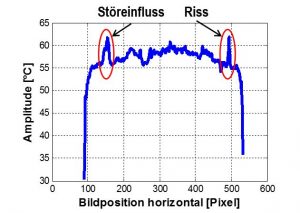

A coil induces an electrical c urrent with high frequency in the region close to the surface of the billet. If there is a crack located in the path of the electrical current, more heat is produced at the crack tips and flanks. A thermal camera is viewing the surface temperature, and an evaluation unit searches for hot spots, which indicates a crack.

urrent with high frequency in the region close to the surface of the billet. If there is a crack located in the path of the electrical current, more heat is produced at the crack tips and flanks. A thermal camera is viewing the surface temperature, and an evaluation unit searches for hot spots, which indicates a crack.

In harsh industrial environment, the thermal data can contain some noise, which could look similar to a crack signal. To suppress false display, the temporal evolution is also evaluated. With this method, cracks can be identified, and robust and stable results will be displayed.

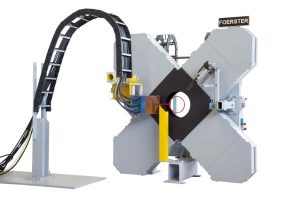

This application was designed for and with our Partner, Institut Dr. Foerster GmbH & Co. KG, who is building and selling this system. You can find more information here.