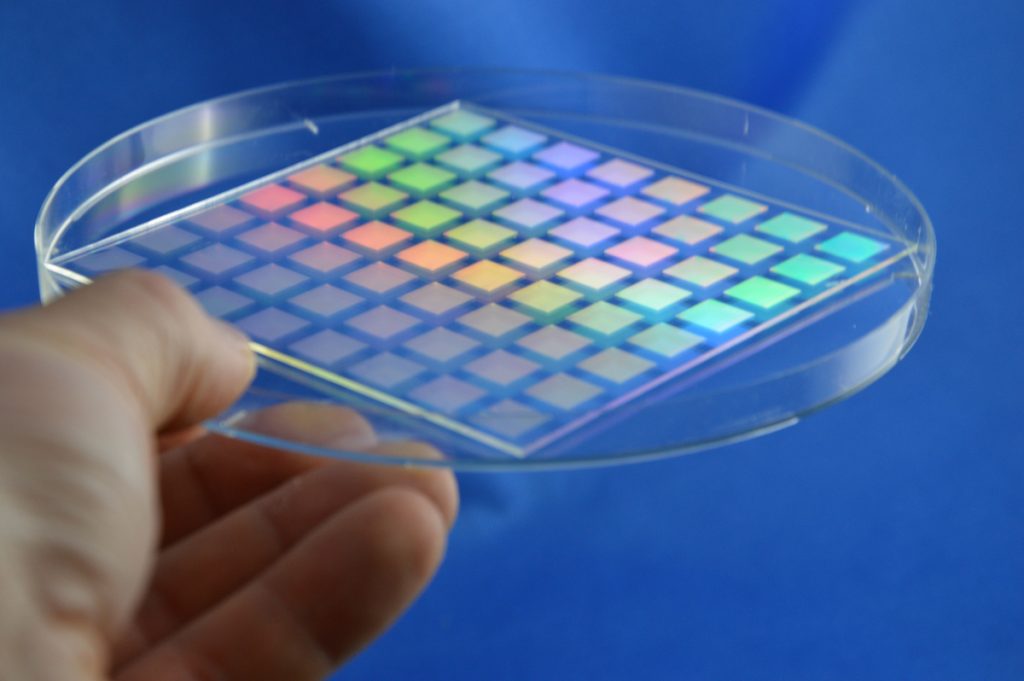

Step & Repeat Technology

Step&Repeat Nanoimprinting (S&R NIL) is a semi-automated process for the fast and cost-effective replication of a small- sized die in a fast and cost-effective way.

This process is very flexible and can be used for a wide range of feature sizes, from some nanometers up to a few hundred micrometers.

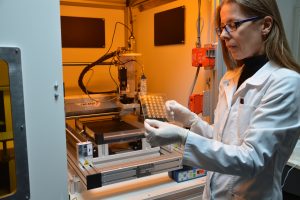

Step & Repeat Lab-Tools

Based on our extensive experience in nanoimprinting research, we have developed specific Step& Repeat tools for laboratory use.

These tools are easy to operate and allow direct process observation.

- Multitool for the replication of microstructures with in-situ resist application

- Soft-NIL-Stepper for the replication of nanostructures on a pre-coated substrate

The tools can be customised to your needs.

You can learn more and gain detailed insight into all functions of the tools during a hands-on workshop in our lab.

Multitool

The multitool enables the fast and precise multiplication of micro- and nanostructures, whereby the resist is applied individually for each imprint.

Advantages

Small footprint. Simple operation and intuitive software.

Specifications

- 4-axis system

- Substrate heating

- Resist dispenser

- Microscope camera

- High-power UV LED module

Soft NIL-Stepper

For the replication of nanostructures.

Specifications

- Up to 360 imprints per hour (depending on material)

- Easy handling and membrane change

- High-performance UV LED module for curing

- Vacuum table for easy mounting of substrates, for example:

- 100 mm wafer

- 1inch × 1 inch glass

- Up to A5 substrate size

- Stage movement (X-Y-Z): 150mm x 150mm x 70mm

- Stamp size up to 15mm x 15 mm

Fields of application

- Research and development laboratories

- Investigation of die life and material properties

- Manufacturing of large-area multi-master templates

- Manufacturing of large quantities of small NIL components