Automation in assembly and logistics with a high number of variants

Many companies are faced with the challenge of having to make assembly and handling processes more efficient and flexible while relieving their employees of monotonous tasks. Traditional automation solutions are not very flexible as they require rigid processes and high quantities.

The use of robotic assistance systems can significantly improve flexibility regarding high variant diversity and small batch sizes. This creates working environments that increase productivity as well as safety and ergonomics. Intuitive operation and the ability of collaborative robots to adapt quickly to new tasks significantly reduce the time and effort required for changeover.

Robotic Assembly

Robot-assisted assembly is a key aspect of modern manufacturing. Hybrid workstations with collaborative robot arms, intuitive operation and integrated sensors for part detection enable greater efficiency and safety in the workplace.

These systems are used in a wide range of joining operations such as the screwing and assembly of components such as cylinder head covers, gearboxes and engine covers or electronic assemblies. They enable a fast assembly process and integrate collaborative tools for safer operation.

Robotic Handling

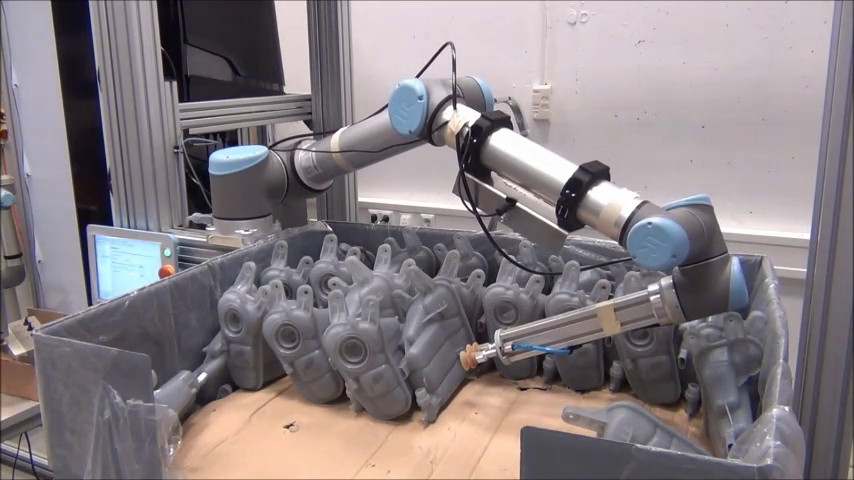

In the area of handling, robotic assistance is revolutionizing the removal, transport and picking of disordered bulk goods and orderly finished goods, relieving employees of strenuous tasks.

By using AI-supported 2D/3D detection of situations, robots can automatically generate optimal paths for handling the components.

The use of adaptable gripping techniques also enables flexible handling of a wide variety of component shapes in bin-picking and bin-packing processes. This means that the handling of a wide range of materials and components such as stamped parts, injection-molded parts, tubes, shafts or rings can be automated.

Industrial Applications

Robotic assembly

Robotic assembly of electrical assemblies

Robotic handling

Robotic handling of water containers