Automation in wood, metal & plastics processing with a high number of variants

In the production of small and medium quantities, employees must repeatedly perform strenuous and monotonous tasks that could not previously be automated due to the high investment costs for traditional robot solutions. This is where robotic assistance systems are setting new standards in wood, metal and plastics processing.

Small, flexible robots in combination with camera-based recognition systems represent an efficient and economical alternative, even in changing manufacturing situations and production with many variants. As a result, employees can be relieved of monotonous tasks and can devote themselves to more important tasks.

At the same time, manufacturing quality can be improved, regardless of whether painting, oiling, gluing or coating is

involved.

Your Benefits

- Very short set-up times thanks to the automatic recording of the workpieces to be processed.

- Flexible and economical even with small batch sizes thanks to intuitive operation and fast order entry.

- Fast commissioning of processes thanks to the use of tried-and-tested hand tools on the robot. This also enables

flexible switching between automated and manual production. - Avoidance of running costs thanks to lower material consumption and reduced cleaning effort.

Industrial Applications

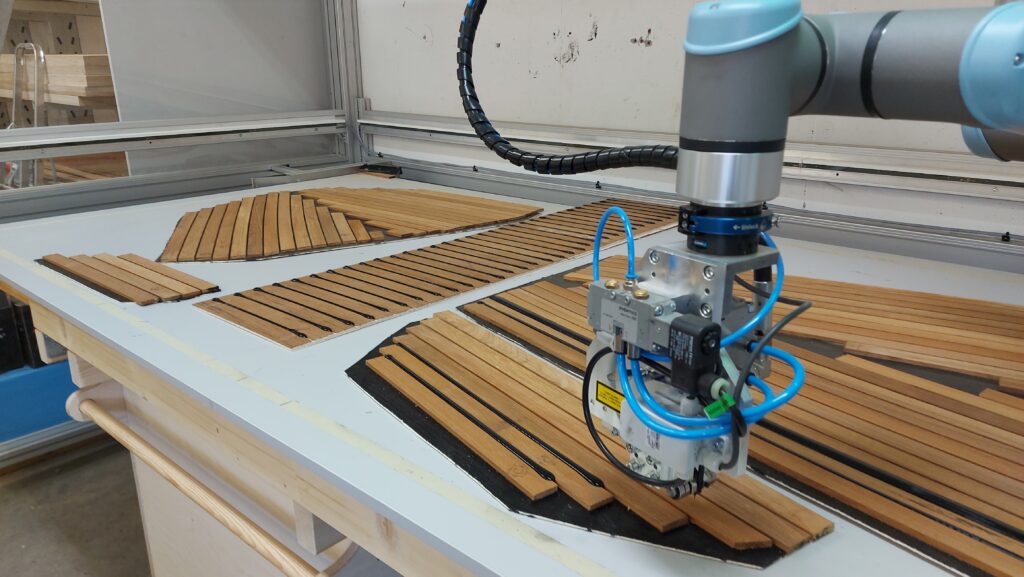

Grouting of boat decks

One good example of the use of robotic assistance is the LIDAUER joinery.

LIDAUER has been successful in the shopfitting, boatbuilding and bespoke furniture sectors for years and uses a

collaborative production system from PROFACTOR for the automated jointing of boat decks for high-end yachts.

Oiling wooden furniture

Further application examples include the oiling of wooden furniture or the application of adhesive to wooden fronts.